Nate B. Nadelen ~ Technology Education Teacher ~ Graduate Student SUNY Oswego On Wednesday, February 16, 2011, about 18 individuals including student teachers and current/former teachers met in Manlius, NY to tour the Voss Sign Company. Opened in 1965, Voss Sign produces a wide range of stock and customs signs using a wide variety of materials and process. Our host and tour guide, Tom Tenerovicz explained to us that Voss Sign customers include: forestry professionals, land owners, state and federal government agencies, school districts, and the general public. Voss Signs specializes in custom signs and also has an inventory of over 250,000 signs available for direct purchase.

On Wednesday, February 16, 2011, about 18 individuals including student teachers and current/former teachers met in Manlius, NY to tour the Voss Sign Company. Opened in 1965, Voss Sign produces a wide range of stock and customs signs using a wide variety of materials and process. Our host and tour guide, Tom Tenerovicz explained to us that Voss Sign customers include: forestry professionals, land owners, state and federal government agencies, school districts, and the general public. Voss Signs specializes in custom signs and also has an inventory of over 250,000 signs available for direct purchase.

On Wednesday, February 16, 2011, about 18 individuals including student teachers and current/former teachers met in Manlius, NY to tour the Voss Sign Company. Opened in 1965, Voss Sign produces a wide range of stock and customs signs using a wide variety of materials and process. Our host and tour guide, Tom Tenerovicz explained to us that Voss Sign customers include: forestry professionals, land owners, state and federal government agencies, school districts, and the general public. Voss Signs specializes in custom signs and also has an inventory of over 250,000 signs available for direct purchase.

On Wednesday, February 16, 2011, about 18 individuals including student teachers and current/former teachers met in Manlius, NY to tour the Voss Sign Company. Opened in 1965, Voss Sign produces a wide range of stock and customs signs using a wide variety of materials and process. Our host and tour guide, Tom Tenerovicz explained to us that Voss Sign customers include: forestry professionals, land owners, state and federal government agencies, school districts, and the general public. Voss Signs specializes in custom signs and also has an inventory of over 250,000 signs available for direct purchase.All Voss Signs are designed and manufactured in house using American materials and state-of-the-art technology and equipment. Voss Signs are typically produced from two main materials: plastic and 100% recycled aluminum. Plastic signs, in gauges from .024 to .125, are made of special high density polyethylene that has UV inhibitors for long term outdoor durability and colorfastness. Aluminum signs are available in .012 and .020-.080 gauges. The .012 gauge signs can be produced with an infinite number of background colors. The .020-.080 gauge signs come standard with a white baked enamel finish with special colors available upon request. Voss Signs’ other materials include self adhesive vinyls, corrugated plastics, magnets, and window/banner materials.

Upon touring the 32,000 square foot facility it is easy to see that Voss Signs believes in lean manufacturing. From the moment that the phone rings in the sales department until the finished product leaves the shipping department, there is no expenditure of resources unless it is creating value for the end

product and customer. Voss Signs’ headquarters and manufacturing facility is set up to produce the highest quality product in the shortest amount of time with attention to detail and customer satisfaction.

With increasing total employment, Voss Signs is showing no “sign” of reduced growth in today’s troublesome economic times. In 2009, Voss Signs expanded by opening The Frame Shop at Voss Signs. The Frame Shop offers a growing list of capabilities that includes: custom mats and framing, artwork mounting, beveled mirrors, plaque mounting, and readymade frames and mats. In 2010, Voss Signs opened its first retail store in Liverpool, NY. The store provides customers with a one stop shop for custom signs, stock signs, sidewalk signs, sandblasted signs, color banners, trade show displays, vehicle graphics, magnets, and decals.

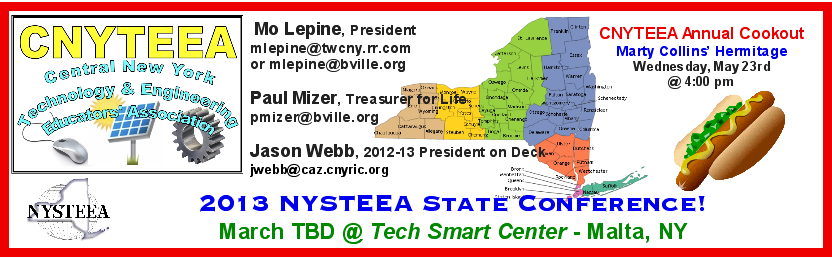

Industry tours offered through the Central New York Technology Education Association (CNYTEA) offer a great opportunity for future and current teachers. The tours offer individuals the opportunity to network with peers while viewing the application of today’s advanced technologies. Many of the conservations during and after the Voss sign tour were evidence of its importance. Conservations included ideas for classroom lessons, laboratory exercises, and student projects. Without periodic connections to real world applications such as the Voss Sign tour, teachers can lose the ability to provide meaningful learning experiences for their students. Do not become one of these teachers, please join CNYTEA at its next industry tour or professional development workshop!